SCM Olimpic K 560 Single-Sided Automatic Edge Bander

The SCM Olimpic K 560 Single-Sided Automatic Edge Bander features high performance and versatility, designed for companies requiring to process many panels per day even though they may be different from one to another. The SCM Olimpic K 560 has several solutions that guarantee always the best machining on any panel type.

High performance and versatility: Olimpic K 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. Olimpic K 560 has several solutions that guarantee always the best machining on any panel type.

Advantages

Perfect joint line

With the “SGP” glue pot thanks to the perfect dosing and the special spreading roller. The use of EVA and Polyurethane glue is made possible by the anti-adherent plasma treatment and a fast and simple glue changeover.

Extraordinary level of finishing quality

With the AirFusion+ technology that allows edgebanding without glue, thus ensuring that the joint between the edge and the panel is invisible.

Perfect results on all surfaces

The controlled axes allow all intermediate positioning of the trimming and edge scraping groups, ensuring optimal edge banding even in the case of surfaces with different degrees of roughness or panels covered with protective film. These units allow the machining of 2 different radii, endless thin edges and solid wood.

"Round X" rounding unit

Productivity and quality with 2 motors technology. The features of the unit allow for the double function of both the simultaneous trimming and rounding operations. The two joint operations, in a single group, require less space and, together with the working distance between panes of only 600 mm, give a reduction in time for the edge banding.

Features

- Automatic single-sided edge bander for the edge gluing with hot melt glue on straight panels, on the four panel sides, finishing and rounding-off of the panel corners.

- Base made of curved and welded steel plates to ensure a vibration free, highly rigid structure. Openings with shoots for the removal of shavings to the floor that are not collected by the dust extraction.

- Top presser made of curved and welded steel plates and supported with steel columns. It provides a vibration free structure on which the operating groups are located. Two rows of high-adherence rubber panel pressure wheels on the track and mounted on bearings. An enclosure covers the wheels. Manual adjustment of presser at the machine's infeed with positioning numerical readout.

- Top operating groups fixed to the presser or mechanically connected on to it to allow the automatic positioning according to the panel thickness. Lower groups fixed to the horizontal beam for a precise reference with respect to the panel. All high frequency motors are equipped with static inverter.

- Safety enclosure on the entire length of the machine with poli-carbonate windows for the groups visualisation during machining.

2 doors for the access to the operating groups; the first one with the only electric interlocking for the gluing unit and the second one with electro-mechanical interlocking for the remaining groups. - Exhaust outlets for the operating groups positioned on the top side of the safety enclosure.

- Mobile control panel at machine infeed for an easy use from the operator's working position.

- Electrical cabinet in conformity with the current safety regulations. Electrical component positioned inside the base with door that allow an easy access in case of any maintenance operations.

- Panel feed track made of pads coated with high friction rubber fixed on 1-1/4” industrial chain, driven by motor controlled by inverter allowing a variable feed speed from 12 to 18 m/min.

- Sliding of pads on two guideways (in hardened steel), one round and one flat, to ensure straightness of movement and resistance to side loads. Manual pads lubrication.

- Panel support rollers positioned parallel to the track. It can be extended on the entire length of the machine. It is made of telescopic opening system and panel sliding plastic wheels with steel pivot pins.

- Safety regulations. The machine is in conformity with thesafety regulations according to the countries of machine destination.

Basic Machines

- R0.02.81: Olimpic K 560 E - Composition (29)

- R0.02.82: Olimpic K 560 T-E - Composition (34)

- R0.02.83: Olimpic K 560 ER2 - Composition (35)

- R0.02.84: Olimpic K 560 T-ER2 - Composition (40)

- R0.03.54: Olimpic K 560 HP T-ER2 - Composition (40)

Machine Compositions

The machine includes the free space for the installation of the following optional groups:

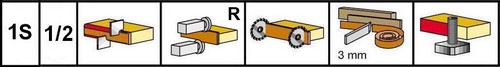

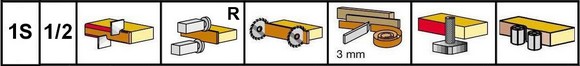

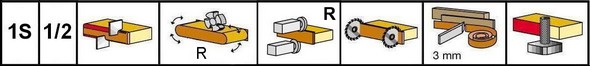

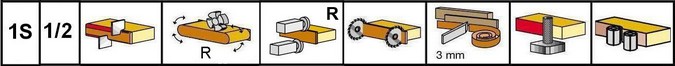

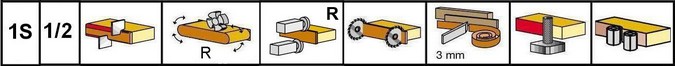

- (1/2): Glue scraping unit

- (1S): Brushing unit

Olimpic K 560 E - Composition (29)

Olimpic K 560 T-E - Composition (34)

Olimpic K 560 ER2 - Composition (35)

Olimpic K 560 T-ER2 - Composition (40)

Olimpic K 560 HP T-ER2 - Composition (40)

Technical Specification

- Variable track feed speed: 12 - 18 m/min

- Panel thickness: 8 - 60 mm

- Thickness of edges in strips: 0.4 - 6 mm

- Thickness of edge in strips (HP composition): 0.4 - 8 mm

- Thickness of rolled edges: 0.4 - 3 mm

- Max. section of rolled edges: 135 mm²

- Coil-holder plate diameter: 780 mm

- Distance between two successive panels: 600 mm

- Minimum panel length (100 mm min. width): 140 mm

- Min. length of edge in rolls: 180 mm

- Min. length of edge in strips: 220 mm

- Min. panel width (210 mm min. length): 95 mm

- 60 mm with units adjustment modification

- Opening for panel support roller: 560 mm

- Worktable height: 900 mm

RT-V PRE-MILLING UNIT:

- Max. removal: 55 mm²

- Max thickness removal: 3 mm

- Panel thickness: 8 - 45 mm (60 mm with H=64mm tools)

- Motors power: 1.5 kW

- Tool diameter: 100 mm

- Tool height: 49 mm

- Tool rotating speed: 9000 rpm

VC-S4.1 GLUE POT UNIT:

- Installed power: 3 kW

- Heating time: 12 min

- Glue pot capacity: 1.5 kg

K-SEL END CUTTING UNIT:

- Motors power: 0.35 kW

- Speed of cutters:12000 rpm

- Manual blades tilting: 0° - 15°

R/K TRIMMING UNIT:

- Motors power: 0.55 kW

- Speed of cutters: 12000 rpm

- Exceeding material to the panel thickness: 2 + 2 mm

- Min. panel thickness with radius: 12 mm

- Vertical/front copying devices: disc / pad

- Knives radius: 2 mm

R-HP TRIMMING UNIT:

- Motors power: 0.65 kW

- Speed of cutters: 12000 rpm

- Exceeding material to the panel thickness: 2 + 3 mm

- 5 mm with edge thickness, 3 mm maximum

- Min. panel thickness with radius: 10 mm

- Vertical/front copying devices: disc / disc

- Knives radius: 2 mm

ROUND X ROUNDING UNIT:

- Motor power: 0.35 kW

- Speed of cutters: 12000 rpm

- Edge thickness: 0.4 - 3 mm

- Panel thickness:

- with a straight angle: 10 - 50 mm

- with a shaped angle (according to the profile): 10 - 30 / 40 mm

- Min. panel length: 140 mm

- Min. panel width: 100 mm

- Max. working speed during rounding operation: 12 m/min

- Max. working speed during only trimming operation: 18 m/min

- Distance between two successive panels: 600 mm

- Vertical/front copying devices: disc / pad

- Knives radius: 2 mm

RAS-K EDGE SCRAPING UNIT:

- Min. panel thickness: 12 mm

- Vertical/front copying devices: disc / disc

- Knives radius: 2 mm

RAS-HP EDGE SCRAPING UNIT:

- Min. panel thickness: 10 mm

- Vertical/front copying devices: disc / disc

- Knives radius: 2 mm

SP-V BRUSHING UNIT:

- Motors power: 0.13 kW

- Speed of cutters: 1400 rpm

| MPN | R0.02.81 |

|---|---|

| Country of Manufacture | Italy |

| Manufacturer | SCM Olimpic |

UK Mainland Delivery

We try our best to dispatch all stock orders same day on a on a next day service. Dispatch times may vary depending on your geographical location and items ordered.

For full terms and conditions please visit our Delivery & Returns page.

Standard* delivery via courier is free for orders over £50 ex vat and under 30kg in weight.

Orders under £50 ex vat and 30kg in weight are subject to a standard* £5.83 ex vat handling and packaging fee.

Stock orders received before 12pm Monday to Friday will be processed and dispatched the same working day. Orders received after 12pm Monday to Friday will be processed and dispatched the next working day (excludes weekends). Standard delivery via courier is free for orders over £50 ex vat and under 30kg in weight. Orders under £50 ex vat and 30kg in weight are subject to a standard £5.83 ex vat handling and packaging fee. Orders over 30kg will be subject to courier or volumetric surcharges.

Orders sent direct from our suppliers are dispatched in accordance to supplier delivery terms.

Laguna: 2 - 3 days, delivery to UK mainland only. A Laguna rep will contact you by phone to arrange delivery that suits you.

Holzmann, Scheppach, Zipper and SIP: 2 - 3 days, delivery to UK mainland only, for Highlands and Islands a delivery surcharge may be applicable, call us on 0141 429 4444 to enquire before you order.

Request a Quote