Japanese Saws Explained

The following information will explain everything you need to know about commonly used Japanese saws and assist you in making your selection. The range of different Japanese saws available can be daunting so we hope that this simple guide will help those who have not yet experienced the pleasures of these stunning tools.

The Pull Saw Cutting Action

The most noticeable design feature of a Japanese saw is that the teeth are angled backwards towards the handle. When in use, the cutting action is on the pull-stroke hence Japanese saws are often referred to as pull saws. The saw is designed to cut as you draw it through the timber, totally the opposite to a traditional western saw. The benefit of the pull saw design is that as much pressure as desired can be applied to the cut without fear of the blade buckling, this method of sawing also ensures far more accurate cutting as a much thinner blade can be employed which in turn reduces friction and speeding up the process.

When a Japanese saw is at work, the blade is under tension rather than compression as is the case with a Western pattern saw. As a result, the blade of a Japanese saw can be made far thinner and of much harder steel. The general problem with Western saw design is after all the compromise; it needs to be thicker and tempered in order to resist buckling under the pushing force when cutting. This in turn makes a western saw heavier and it will require much more frequent sharpening because of the softer steel employed. The Japanese saw is therefore naturally a great deal lighter in weight and the teeth retain their sharp edge much longer. The harder steel has allowed the geometry of the Japanese saws teeth to evolve differently. This is most noticeable on the crosscut saws where the teeth are long and fine. A close inspection will reveal not one but up to three cutting edges on each tooth. The teeth literally slice through the wood fibres like a series of super sharp knives leaving the smoothest of cut surfaces, almost planed, rather than sawn.

Rip cutting teeth look very similar to Western teeth, the triangular chisel type. Being so thin, means removing far less material from the actual cut, on average the kerf is at most only a third of a similar Western saw. This means, the worker only expends a third of the energy to achieve the same result and will finish the job much quicker.

Styles of Japanese Saw

Japanese saws fall into three basic styles. The single edged backless saws referred to as a Kataba or Hassunme, the double-edged or Ryoba and a single edged saw with a stiffening spine known as a Dozuki. There are also slight variations within each category for more specialist functions.

Kataba / Hassunme Saws

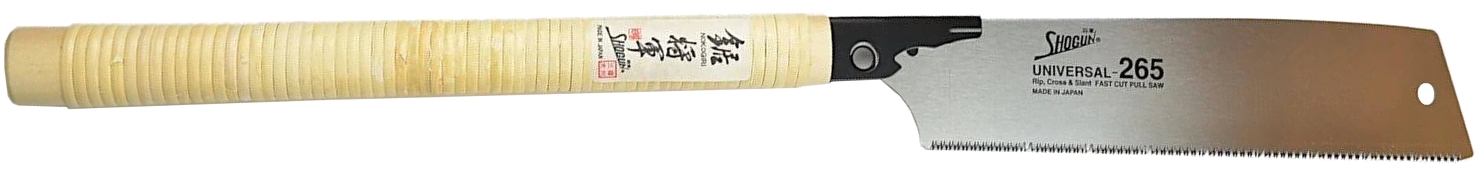

The Kataba / Hassunme saws, having no spine are ideally suited for deeper cuts. These are the equivalents of western rip and panel saws. Examples in our Shogun range are the Hassunme universal and crosscut saws plus the Kataba craft saws all of which feature replaceable blades. They will retain their sharp edge for a considerable amount of time, but once dull it is a simple task to change the blade.

The handles of both our Hassunme saws have identical fittings so it is possible to purchase one saw and a replacement blade of the other type, just change from one to the other as and when required. A further benefit; removing the handle means the saw will fit neatly into a toolbox.

Shogun OK265RC Hassunme Saw

Kugihiki Saws

The Kugihiki or flush cutting saw has an exceptionally thin and flexible blade. The teeth have no set; it is perfect for cutting the protruding ends of through tenons or dowels without damage to the surrounding area. When using this saw, it helps if you gently rest the fingers of your free hand on the back of the blade just behind the cut. This gives much greater control.

Shogun FL150 Flush Cut Saw

Ryoba Saws

The most spectacular looking of all Japanese saws is the double-edged Ryoba style. Surprisingly, it is a recent addition to the Japanese woodworker’s toolbox, originating just over 100 years ago or so. In reality, it is a type of crosscut and a rip cut Kataba back to back on a single handle. Instead of carrying two saws the woodworker only requires one dual purpose saw, a little less weight to carry around and a good deal lighter on the pocket.

The Ryoba in our opinion must be the ultimate tenon saw, one edge for ripping down the cheeks and the other to cleanly crosscut the shoulders. Our professional quality Ryoba saw from Shogun is exceptionally well balanced making it a real pleasure to use and features a replaceable blade.

Shogun MC2424H Ryoba Saw

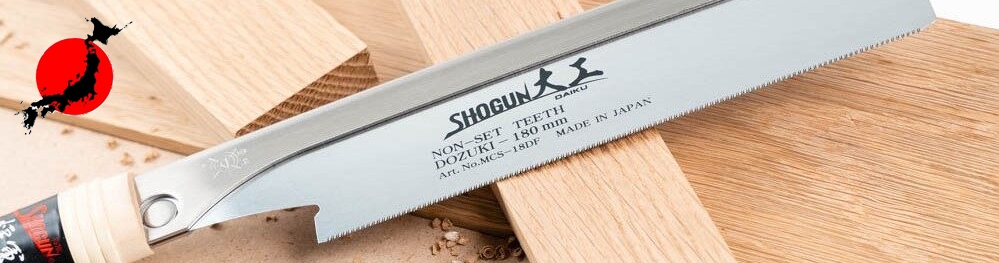

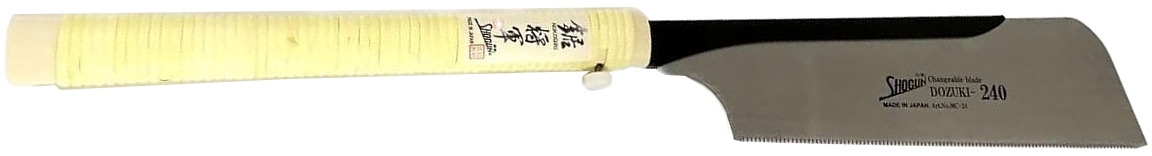

Dozuki Saws

Within the range of Shogun Dozuki saws is the MC24. This has a blade thickness of a mere 0.3mm. Such a thin blade requires a steel spine to give it rigidity. In a similar way to a western tenon saw, the weight of the back provides the necessary downward pressure to ensure a smooth cutting action. This saw also features a replaceable blade 20 tpi blade. For deeper cuts we offer the MCW24H which features a super fine 0.25mm thick blade with 24 tpi toothing.

Shogun MC24 Dozuki Saw

Shogun MCW24H Dozuki Saw

Also in this range is our hugely popular MP150 mini Dozuki saw. Specifically deisgned for cutting small intricate joints down the grain, the dovetail comes immediately to mind. This is where the MP150 has earned a solid reputation in the education sector. Another Dozuki is the MCD240, a classic style professional saw with a fixed blade of 0.3mm thickness and 20 tpi, this saw is ideal when very precise thin-kerf cuts are required.

Shogun MP150 Mini Dozuki Saw

Shogun MCD240 Professional Dozuki Saw

To get the most from a Japanese saw the main thing is to relax and the saw do all the work. The only thing for the woodworker to do is to provide the backward and forwards motion. Either pushing or trying to force the saw to cut can result in one of two things; the blade will buckle or a tooth may snap off. Don't worry if the odd tooth gets broken, which can happen in very hard woods, this will not affect the saw's performance. It matters not whether you hold the handle near the blade or at the far end, whichever feels most comfortable is correct, a good quality Japanese saw such as Shogun will stay on line.