Saw Blade Sharpening & Tool Regrinding

Quick Access Links: Saw Blade Sharpening | Tooling Regrinding | CNC Manufactured Form Tools

Saw Blade Sharpening Service

At The Saw Centre we pride ourselves on our saw sharpening service. We are one of the few companies in the UK who still has a Saw Doctor providing our customers with quality services and has been for almost forty years. Over the years we have invested heavily in state-of-the-art CNC saw blade regrinding machinery for TCT circular saw blade sharpening and HSS circular saw blade sharpening. This machinery allowed us to take our sawblade sharpening service to the next level.

New Online Saw Blade Sharpening Service

Now you can purchase our saw blade sharpening service online! Use the links below and get your blades sharpened in our state-of-the-art cnc factory.

TCT Saw Blade Sharpening Service

Festool Saw Blade Sharpening Service

HSS Cold Saw Blade Sharpening Service

Simply add the diameters of blades you need sharpened and the quantities to your cart, add the Saw Blade Sharpening Collection Service if required and checkout. Then send your blades to us or await collection. We'll get your blades back to you within a week sharper than ever.

Vollmer CNC Service Centre Machinery

Our state-of-the-art Vollmer CNC machining centre has the ability to be loaded with up to 120 saw blades at a time which are then sharpened automatically with the aid of our robot loader. This allows us to sharpen saw blades almost 24 hours a day providing fast turn around times for our customers whilst maintaining the highest standards of efficiency and accuracy possible in saw blade sharpening.

TCT Saw Blade Sharpening

Consistent finish to blades using the same geometry as manufacturer. Any damage teeth are replaced using high quality carbide tips. All blades are chemically cleaned in high pressure tank and given a wax coating to protect blade when in transit.

With The Saw Centres new investment in the latest saw sharpening technology, we are one of the only companies in the UK who are able to correctly service and sharpen the NEW Festool plunge saw blades. These blades have a tooth trajectory that cannot be replicated on most current saw sharpening machines and incorrectly sharpening these saw blades ruins the tooth trajectory and dramatically decreases cutting performance.

Send your blades to The Saw Centre to ensure you get the quality of cut your New Festool plunge saw requires.

HSS Saw Blade Sharpening

Blunt blades are sharpened with minimal material wear in our CNC machine factory. This fast, efficient and reliable service is perfect for sharpening your HSS cold saw blades and the process can be repeated multiple times before any significant reduction in diameter occurs.

Damaged cold saw blades can be cut and re-ground, if teeth are missing we strip the teeth off and re-cut new teeth losing you a few millimeters from the diamter and cutting depth of the blade, if your blade is cracked material needs to be stripped off the blade beyond the point where the crack appears before teeth can be re-cut.

We can also perform geometry reconfiguration on your cold saw blade to suit your specific cutting application. Most blades are configured for either mild steel or stainless steel and the cutting teeth perform in different ways and at different speeds to accomplish a clean cut on various materials.

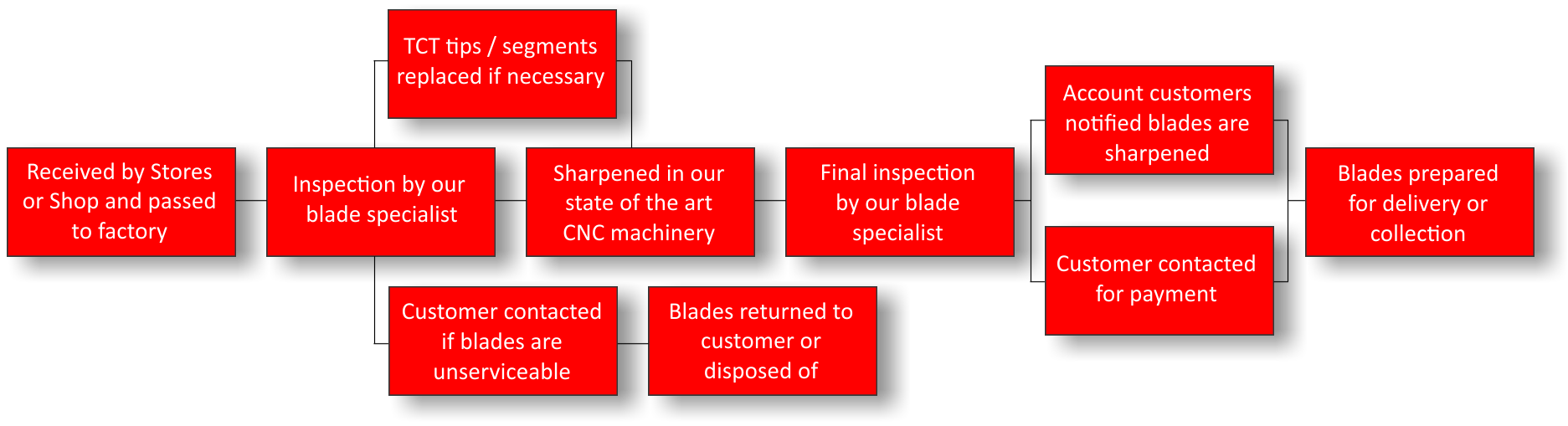

Getting Your Blades Sharpened at The Saw Centre

The flow diagram below quickly describes the processes undertaken to get your blades to us, have them sharpened and then have your blades returned or prepared for collection.

Sending Your Saw Blades for Sharpening

Please ensure that your blades are securely packaged before you send them to us. If your sawblades have any free movement within the packaging they are at high risk of being damaged or broken during transportation, it's very easy for TCT saw blades to have teeth broken off and it's even easier for HSS saw blades to break because they are very brittle. So package them tight and secure and save yourself from any extra costs that could easily be avoided.

Please include your contact details and a return address so that we can contact you for payment and send them back to the correct address. If you are an account customer please also include any relevant purchase order forms complete with order numbers.

Send your blades to our address:

Sharpening DepartmentThe Saw Centre

650 Eglinton Street

Glasgow

G5 9RP

Area Van Sales and Collection Service

We have a fleet of area sales vans that cover large areas of Scotland. If you would like to arrange a collection service for saw blade sharpening we may be able to send one of our area sales representatives in to your business.

Please view the Area Van Sales page for more information.

If you are outwith Scotland but still within the UK we may arrange for a courier to collect your blades if there are a large number of them or if your blades have a very large diameter.

Tooling and Cutter Regrinding

At The Saw Centre we have state-of-the-art Vollmer CNC machinery which allows us to sharpen almost any type of industrial tooling or cutter.

Getting Your Tooling Reground at The Saw Centre

The flow diagram below quickly describes the processes undertaken to get your tools to us, have them sharpened and then have your tools returned or prepared for collection.

Types of Tooling Which Can Be Sharpened

End Mills

End mills can be reground on the flutes to remove the wear, when possible we regrind the inside of the flutes to maintain as much of the diameter as possible. Grinding on the outside of the flutes reduces more of the diameter however it is only done when the wears is more severe.

Alternatively, if a short portion of the tool length is worn i.e. the end 6mm. We can cut off the worn portion and regrind new end teeth. The tool is returned with original diameter but a little shorter in length.

Slot Drills

Slot drills are used to machine slots and the cutter size is important. In this case the cutter has been worn to the depth of the slot. We can refurbish the tool by removing the worn section and regrinding new end teeth. The tool is returned with original diameter but a little shorter in length.

Alternatively, many customers prefer to use these two flute cutters for machining aluminium or plastic and require the worn diameter to be sharpened. In this case we regrind the diameter and sharpen the end teeth.

Ball Radius End Mills

Many customers use only the ball radius and a small section of the cutter diameter and in this case we can remove the worn portion and CNC regrind the ball radius. The tool is returned with original size and ball radius but a little shorter in length.

Ripper Cutters

Ripper Cutters are restored by grinding inside the flutes to clear wear. Although the profile on the diameter is form relieved the amount removed from inside the flutes does not significantly reduce the size of the tool.

Many Ripper Cutters are only used for shallow cuts and the worn part of the flutes can be cut off and new end teeth reground. The cutter is then returned with the original diameter size but slightly shorter in length.

Counter Boring Tools

Counter Boring tools wear on the end cutting face and can easily be restored by grinding the end teeth back to an unworn section. The tool is returned without alteration to the original counter boring diameter.

Corner Rounding Tools

Corner rounding cutters can often be refurbished by regrinding the tooth face to remove wear. If the tool is severely worn, it can be reground to a new radius.

Dovetail Cutters

Dovetail cutters can be reground on the side angles and on the end teeth to remove tool wear. New tools are often modified to suit particular customer requirements.

Countersink Tools

Countersink tools can be reground to remove wear – often very little material needs to be removed and these tools can have a very long life if re-sharpened before severe wear takes place.

Threading Taps

Various types of threading tap can be sharpened. Typically the tool is ready for regrinding when the first full thread is chipped or worn - visually 2 or 3 pitches are cut off and the lead renewed.

Face Mills

Face mills or shell mills usually have deep teeth and flutes that will allow several re-sharpening and regrinding operations before the tool begins to loose cutting efficiency.

Tee Slot Cutters

Tee slot cutters are available in a number of different styles and can be re-sharpened when worn.

Slab Mills

Slab Mills have a large variety of diameter sizes and lengths and can be reground to remove wear.

Broaching Cutters

Frequently these tools will be sent for refurbishment with one or more broken teeth. Typically we are able to refurbish these tools by removing and grinding the broken section to restore a complete set of sharp teeth.

Drills

We sharpen all drills from your standard HSS jobber drills to 80mm taper shank drills. We have the ability to grind carbide drills and your thru-coolant chipbreaker drills for the structural steel industry. We grind any form and angle on to the drill which best suits the application.

CNC Manufactured Form Tools

We operate state-of-the-art CNC Machinery to manufacture a full range of form tools in house. These can be carbide tools, step drills, brazed tip forms and tools made from M42 blank steel to suit weld preparation or cutting.

To learn more about this service please use the Contact Us page to get in touch.