What are HSS Cold Saw Blades used for?

HSS circular cold saw blades are primarily used to cut a variety of metals and steel alloys with a tensile strength < 500 N/mm² and < 1200 N/mm². The material used for HSS saw blades is generally referred to as DMo5 which is a high speed tungsten-molybdenum steel conforming to European standard DIN 1.3343.

This well-balanced alloy composition results in a very high material hardness which is not reduced during cutting even when reaching temperatures of 600 °C which makes it the perfect material for a wide range of metal cutting applications. Tungsten in HSS saw blades increases the endurance and cutting performance whilst preventing austenitic grain enlargement (deformation and grain growth on the blade) and the molybdenum content provides a fine martensitic structure (very hard and brittle needle shaped molecules) creating a mechanically resistant and hard wearing material perfect for cutting metals.

Different types of HSS saw blade

DMo5 / SHSS

High speed tungsten-molybdenum steel containing 5% molybdenum. Can be used to cut a wide variety of metals including mild steel and stainless steel.

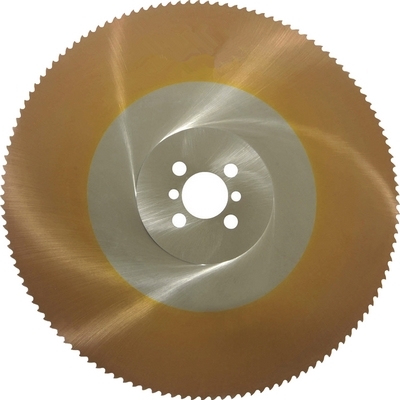

Shop for DMo5 HSS Cold Saw BladesTiN Coated

HSS DMo5 saw blade coated in Titanium Nitride (TiN) provides increased surface hardness and excellent finish during the cutting process due to a low coefficient of friction.

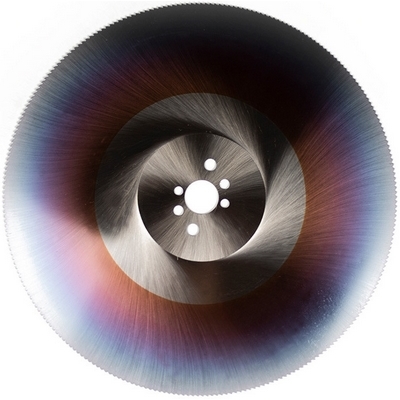

Shop for TiN Coated HSS Cold Saw BladesCo5 Cobalt

High speed tungsten-molybdenum-cobalt steel containing 5% cobalt. HSS Co5 should be used only to cut hard materials like stainless steels or high tension steels.

Shop for Co5 Cobalt HSS Cold Saw BladesWhat materials do circular HSS saw blades cut?

High speed steel cold saw blades are perfect for cutting steel profiles, extrusions, tubes, pipes, sheets, plates and bar stock. These materials are commonly made from mild or high carbon steel and stainless steel. HSS blades are also commonly used to cut cast iron, brass, copper, bronze, aluminium and zinc alloys. Extremely hard materials such as Inconel and titanium can be cut efficiently using a cobalt HSS Co5 saw blade.

Oils and lubricants for cutting steel with HSS saw blades

The use of cutting fluids and coolant whilst cutting metal is vital, the friction generates a large amount of heat where the blade meets the material. Cutting metal without lubrication causes a reduced quality of cut and increases the wear of the blade. We recommend using SAWCUT or SPRAYCUT when using HSS cold saw blades to cut metal.

Soluble Cutting Oil

Soluble cutting fluid for metal working is an EP620S water mix concentrate suitable for cutting mild to high carbon steel, tool steel and stainless steel.

Mild to high carbon steel: 1 part SAWCUT in 10 parts water

Tool and Stainless Steel: 1 part SAWCUT in 5 parts water

Spray Misting Lubricating Oil

Spray systems oil for all sawing ferrous and non-ferrous metals (ZS06). Use SPRAYCUT with spray misting equipment and apply directly to the cutting surface for improved lubricity, cutting performance and tool life.

Shop for metal cutting spray mistCan HSS cold saw blades be sharpened?

Yes! Get your HSS cold saw blades sharpened and reground in our state-of-the-art CNC factory. Our fast, reliable and extremely efficient saw blade grinding service provides you with quick turn around times and cold saw blades which are like new. You can now purchase HSS cold saw sharpening online with The Saw Centre.

Visit our HSS Saw Blade Sharpening Service page:

Follow these simple steps to get your HSS cold saw blades sharpened at The Saw Centre:

1. Simply select the diameter of your saw blade using the option below and then select a quantity before adding it to your basket. Do this for every different diameter of blade you require sharpening.

2. Add the DHL Collection Service product to your cart to arrange collection of your blades via courier if required.

3. Checkout and pay for your blade sharpening.

4. Send your blades to us or await collection.