SCM Class SI 350 Sliding Table Saw with Blade Tilting

The SCM Class SI 350 Sliding Table Saw with Blade Tilting features high construction quality for reliability and safe performance.

The SCM Class SI 350 Sliding Table Saw with Blade Tilting features high construction quality for reliability and safe performance.

Advantages

Saw unit: a perfect cut.

Maximum torsional rigidity and the total absence of vibration through the closed loop structure of the saw unit which ensures perfect alignment of the blades during tilted and difficult cuts.

Sliding carriage: maximum cut quality guaranteed over time.

The carriage will never require adjustment due to its structure with arch-ground steel slideways (developed by SCM).

Manual movements: always user friendly and precise.

Ease of use in every day operation due to the dedicated gear box, fully protected from dust (SCM patented solution), that provides a smooth and direct transmission. Every minimum handwheel movement corresponds to a precise blade adjustment.

Manual adjustment of the scoring unit: simple and effective.

Vertical and horizontal adjustments are carried out by user-friendly mechanical levers that operate directly making precise and smooth movements. The useful mechanical stops allows immediately finding of the set position. The positioning of the controls allows their use without moving from the front of the machine.

Standard Equipment

- 10 years guarantee for the carriage sliding system

- Anodized aluminium alloy sliding carriage sliding on high precision "arch-formed" hardened steel guides, which are fixed on the carriage by means of mechanical bending system

- Lifting and tilting of saw unit by means of handwheels on the machine front side and mechanical readout of saw unit tilt

- Eccentric clamp

- Squaring frame for the fast fence positioning of angular cuttings

- Outfeed table extensions

- Sliding carriage length 3200 mm

- Manual parallel fence with position readout on metric rule, with sliding system on 40mm steel bar and micrometric adjustment

- Direct start main motor with pushbuttons

- 3 phase motor 7kW (9.5hp) 50Hz with direct motor start

- Independent powered scoring unit with external setting up and stops for a quick re-positioning of the blade

Safety Equipment

- Emergency pushbutton located on the front machine side

- Emergency pushbuttons located on parallel fence side (CE version)

- Blade access door with quick locking (C.E. version) and safety microswitch

- Overload protection

- Overhead saw guard (CE version)

- Automatic brake on main sawblade (CE version)

- Padlockable main switch

- Auxiliary low voltage circuit (110 voltage)

- Certificate of conformity with "C.E. Standards" (CE version)

Technical Specification

- Max cutting height at 90°: 118 mm

- Max cutting height at 45°: 81 mm

- Blade tilt: 45°

- Blades lifting and tilt: manual

- Main blade rotating speed: 4000 rpm

- Scoring unit rotating speed: 8500 rpm

- Saw unit motor power: 7 kW (9.5 HP) 50 Hz

- Scoring unit motor power: 1.3 kW (1.7 hp) 50 Hz

- Squaring capacity: 3200 x 3200 mm / 3200 x 3800 mm

- Cutting width on parallel fence: 1270 mm

- Exhaust outlet diameter:

- at the base: 120 mm

- on overhead protection: 100 mm

- on riving knife: 60 mm

Optional Extras

- 11.02.40: Sliding carriage length 3800mm. Squaring capacity with scorer 3800mm

- 57.03.45: Sliding carriage length 2200 mm

Squaring capacity with scorer 2200 mm - 57.03.41: Surface reinforcement treatment for sliding table and mobile crossbars of squaring frame dedicated to the intensive processing and particularly abrasive materials

- N.B.: Not available for "Sliding carriage length 2200 mm"

- 95.11.06: Motor start/stop pushbuttons integrated in the sliding carriage for saw and scoring blade

- 57.02.27: "Quick Lock" squaring fence with simultaneous positioning and locking/unlocking on the frame. It is complete with the roller for workpiece support of 2400 mm from the blade

- N.B.: A fence for angular cutting has is compulsorily

- 57.00.42: Squaring fence with no. 3 LCD readouts for stops position. Each stop is equipped with electronic digital readout with detecting system on magnetic band and readout on LCD display

- 57.00.51: Fence for angular cutting on sliding carriage

complete with extended stop for cutting sizes up to 1500 mm - 57.00.44: Fence for angular cutting with self-adjustment of the stop position in respect of the blade, irrespective of the angles

used, complete with aluminium fence with stop for sizes up to 1500 mm. - 57.00.30: Fence for angular cutting with electronic readouts

with self-adjustment of the stop position in respect of the blade, irrespective of the angles used. Aluminium fence with stop for sizes up to 1500 mm. Independent electronic readouts of stop position and rule tilting angle.

Detecting system on magnetic band and readouts on LCD display. - 57.03.09: Squaring frame with CompeX device for angular cutting with automatic self-adjustment of the stop position. This exclusive system allows the functioning even when the optional fence for complementary cuts is applied

- N.B.: not compatible with Quick Lock device

- 57.03.10: Fence for complementary cuttings

to be applied to the squaring fence supplied as standard feature - 57.00.45: Fence for parallel cutting on the sliding carriage

utilizing the carriage, complete with millimetric rule, extended stop - 57.00.41: Fence for parallel cuttings on the sliding carriage with electronic readout for rapid fixing on the carriage. Complete with electronic digital readout with detecting system on magnetic band and readout on LCD display. It is equipped with extended stop for cutting sizes up to 1000 mm and millimetric reference system for the first trim cut.

- 57.02.29: Electronic readout of parallel fence position

with manual adjustment and:

- selector for high/low fence position and preset switches

- electronic readout of parallel fence position and sliding fence on bar 50 mm diameter

- position readout on magnetic band

- possibility of incremental movings

- 28.01.36: Ripping capacity on parallel fence 1000 mm

- 28.01.35: Ripping capacity on parallel fence 1500 mm

- 31.12.40: Presser on entire carriage length complete with no. 2 pneumatic pressers with centralized control and working capacity:

- 3030 mm with sliding carriage length 3200

- 3650 mm with sliding carriage length 3800

- 57.00.16: Second support frame with sliding rail for supporting panels of large dimensions

- 53.03.40: Expandable scoring blade

- Min. / max. thickness: 2.8 / 3.6 mm

- Blade diameter: 120 mm

- Bore diameter: 20 mm

- Number of teeth: Z 24

- 57.03.42: Additional eccentric clamp

Advanced Material Processing

- 53.03.30: Machine configuration for the machining of advanced materials. This configuration makes the machine suitable also for the machining of cork, stiff rubber or plastic and plastic-coated plywood. Metals and cement-wood base composite are excluded.

- 53.03.16: Device for the blade micro-lubrication to machine plastic materials and light alloys of aluminium and brass with quantity adjusting system of the sprayed liquid lubrication

N.B.: The device is compulsory for the machining of light alloys of aluminum and brass, particularly useful with certain plastic materials

| MPN | R1.07.29 |

|---|---|

| Country of Manufacture | Italy |

| Manufacturer | SCM Class |

UK Mainland Delivery

We try our best to dispatch all stock orders same day on a on a next day service. Dispatch times may vary depending on your geographical location and items ordered.

For full terms and conditions please visit our Delivery & Returns page.

Standard* delivery via courier is free for orders over £50 ex vat and under 30kg in weight.

Orders under £50 ex vat and 30kg in weight are subject to a standard* £5.83 ex vat handling and packaging fee.

Stock orders received before 12pm Monday to Friday will be processed and dispatched the same working day. Orders received after 12pm Monday to Friday will be processed and dispatched the next working day (excludes weekends). Standard delivery via courier is free for orders over £50 ex vat and under 30kg in weight. Orders under £50 ex vat and 30kg in weight are subject to a standard £5.83 ex vat handling and packaging fee. Orders over 30kg will be subject to courier or volumetric surcharges.

Orders sent direct from our suppliers are dispatched in accordance to supplier delivery terms.

Laguna: 2 - 3 days, delivery to UK mainland only. A Laguna rep will contact you by phone to arrange delivery that suits you.

Holzmann, Scheppach, Zipper and SIP: 2 - 3 days, delivery to UK mainland only, for Highlands and Islands a delivery surcharge may be applicable, call us on 0141 429 4444 to enquire before you order.

Upsell Products

Festool TKS 80 EBS-Set Table Saw 240V

Holzmann TKS500S 500mm Construction Site Table Saw

Sedgwick TA315 Tilt Arbor Saw Bench 315mm Three Phase

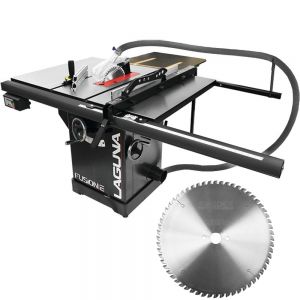

Laguna FUSION2 Table Saw with Free 250mm Saw Blade

Laguna FUSION3 Table Saw with Free 250mm Saw Blade

SCM Nova SI400 Sliding Table Saw with Tilting Blade

DeWalt DWE7485 210mm Compact Table Saw

SIP 01332 10" Professional Cast Iron Table Saw

SIP 01446 12" Cast Iron Table Saw

SIP 01447 Sliding Carriage for 01446 Cast Iron Table Saw

SIP 01986 10" Table Saw with Stand

Request a Quote